Der Indutainer

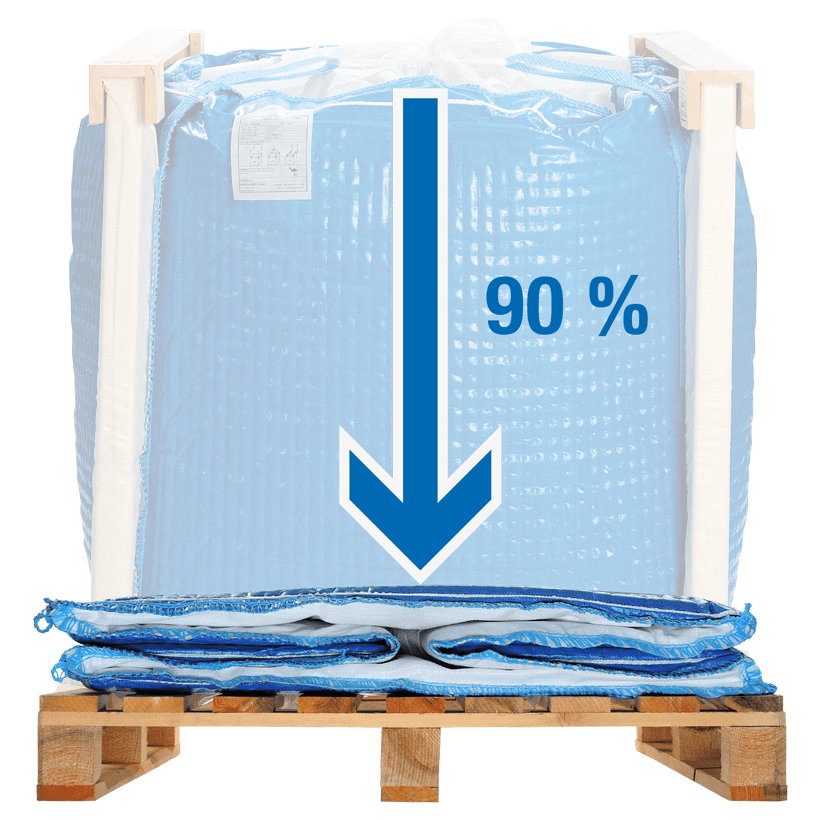

Bei der Entwicklung des Indutainer IBC waren die Parameter Wirtschaftlichkeit, Handling sowie ein geringes Lagervolumen Wegbegleiter der Forschungs- und Entwicklungsabteilung. Anspruch war es, ein faltbares Containersystem zu entwickeln, das die Vorteile der starren Container (RIBC) mit den Vorzügen der flexiblen Container (FIBC) kombiniert.

Aufgrund immer neuer Herausforderungen des Marktes und der gestiegenen Anforderungen in den Bereichen Umwelt und Nachhaltigkeit befinden wir uns in einem stetigen Entwicklungsprozess.

Vielfältige weitere Anwendungen des Indutainer IBCs sind hinzugekommen. So findet er zum Beispiel als mobiler Damm bei Überschwemmungen, als Durchfahrsperre für den Bevölkerungsschutz bei Veranstaltungen oder als mobiler Löschwasserbehälter bei den Feuerwehren Verwendung. Auch zur Bewässerung von Grünflächen kann der Indutainer eingesetzt werden.

Indutainer IBCs sind „Made in Germany“ und werden mit viel Herzblut bei Indutainer im westfälischen Greven hergestellt. Jeder einzelne faltbare Container wird vor der Auslieferung auf „Herz und Nieren“ geprüft. Und so erfüllt eine konstant hohe Qualität aller Indutainer die täglichen Erfordernisse der geschätzten Kundschaft.

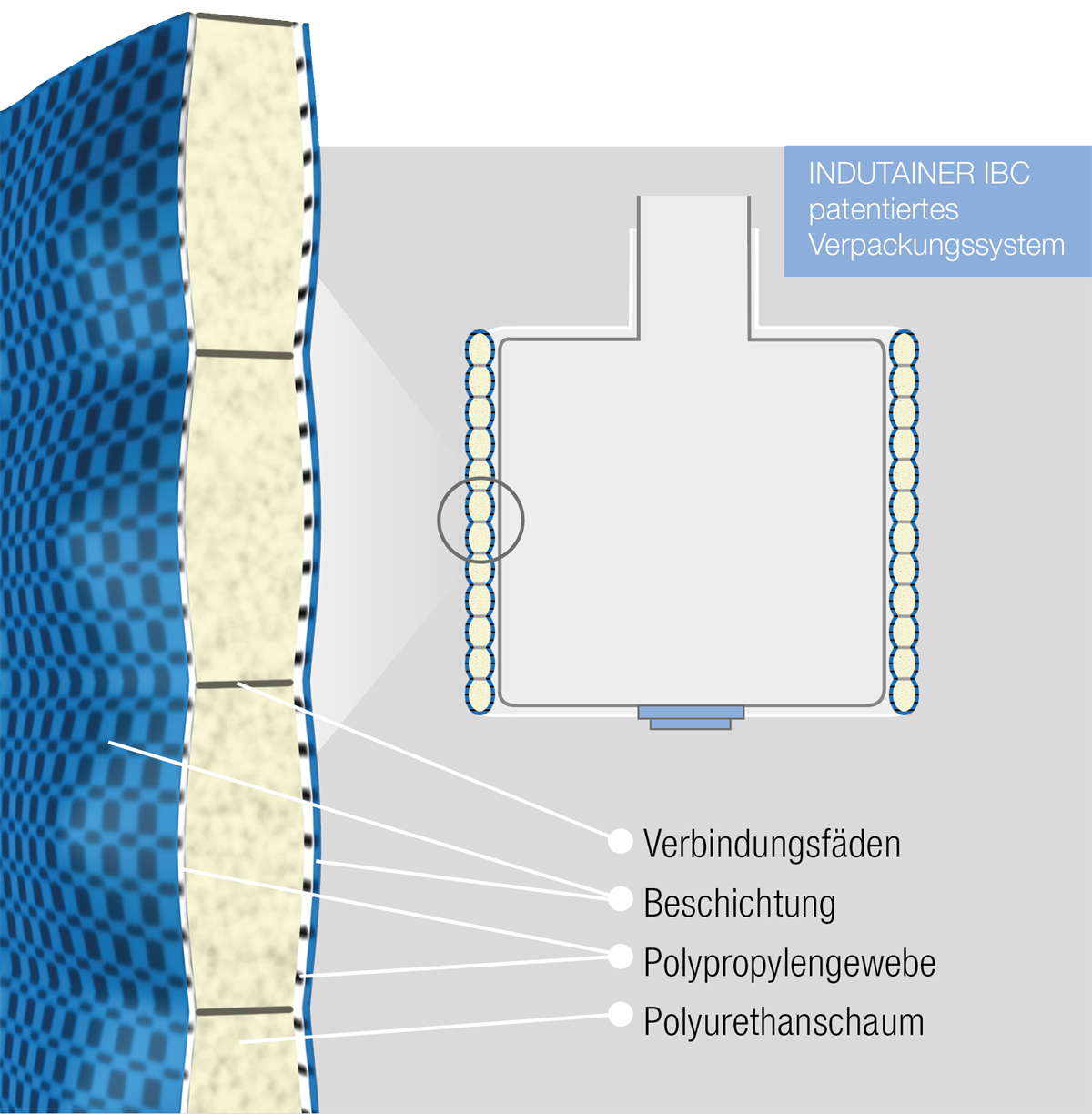

Indutainer IBC Wandaufbau

Patentiertes Verpackungssystem

Das mit Polyurethan ausgeschäumte Doppelabstandsgewebe der Seitenwände gibt dem Indutainer IBC die notwendige Standfestigkeit für Flüssigkeiten.

Somit ist der Indutainer IBC bestens geeignet für den Transport und die Lagerung von mittel bis hoch viskosen Produkten und sedimentierendem Schlamm.

Get Social